Waiting to Upgrade: The Best Way to Waste Money

There are things that we fully intend to get around to doing. I’m going to clean the gutters. Take out the trash. Return that phone call. I really am going to do them! ...Eventually. And that’s how most businesses and individuals approach upgrading their lighting. It feels daunting and, let’s face it, it feels like something that can wait. Well there are very good reasons beyond just the energy savings why waiting is not advisable.

Admittedly a single household is going to see fewer of these benefits, or not notice them as much as a larger installation will. However, if you’re responsible for a multifamily building, commercial installation, warehouse, or even an large-scale industrial building, you’re going to benefit, and substantially, from upgrading to LED sooner rather than later.

Energy cost

The first, and most easily measurable thing to consider is the energy savings from upgrading to LED. Traditional light sources especially incandescents and halogens are up to 90 percent less efficient than LEDs. The best way to illustrate this is to take a look at how much energy your current lighting is using, what that’s costing you, and then comparing that to what replacement LEDs would cost to operate for those same fixtures.

There’s a relatively simple way to figure this out.

[Total watts of lighting] X [Total hours operated] / 1000 = Total energy used over a time period (in kWh)

For example, if you were to run 100 light fixtures that use a 60W incandescent bulb for 10 hours a day during a 30 day month, your total watts would be 6000W and your total hours would be 300.

6000 watts x 300 hours / 1000 = 1800 kWh of electricity.

A good national average electricity cost is $0.11 per kWh. That one month of electricity using incandescent bulbs is going to cost you somewhere in the neighborhood of $198.

Upgrading to a 60W equivalent LED bulb, which only draws 9W of electricity to achieve the same illumination, you could cut that cost to around $30 for that same month-long period.

Everyone’s individual situation is different of course, but just looking at these numbers it’s easy to see how the cost of waiting to upgrade compounds with every month that goes by.

HVAC costs

Traditional lighting, especially incandescents, are extremely efficient...at producing heat. As small space heaters, they’re great. As light sources, they leave a lot to be desired. What it comes down to is that running a fair amount of incandescent and especially halogen bulbs in an enclosed space can cause the room to heat up by a not-insignificant amount. That may not be the worst thing in the winter months in colder climates, but during the warmer months that extra heat taxes any air conditioning system you may have running.

Believe it or not there’s a relatively easy way to calculate how much you’re taxing your HVAC to offset the cost of running your antiquated, inefficient light bulbs. I say relatively easy, because it does require you to do some leg work to get the variables worked out, but the formulae aren’t terribly complex. Let’s go through the exercise using our example above.

In our first example, you were using 1800 kWh per month to power those 100 incandescent fixtures. By switching to LED, you’d be using about 270 kWh for those same bulbs over that same 30-day period. That’s an energy savings of 1530 kWh. If you multiply that by 12 months, you get 18,360 kWh savings per year.

These numbers are getting pretty big. We initially said we were running 100 bulbs, let’s take our energy savings total, and divide it by 100 to get the per-bulb savings.

Annually, we’re saving 183.6 kWh per bulb by switching from a standard A19 60W bulb to a 9W LED equivalent.

A good estimate of price per kWh is about $0.11. If we plug in our variables: 183.6 (kWh savings) x $0.11 (cost per kWh) = $20.20 annual savings per bulb. Multiply that by our 100 bulbs, and you get $2,020 in savings just on the cost of running the bulbs alone.

Next we’ll need to know how many months we’re typically going to be running air conditioners. Assuming we’re in a place like Chicago with temperate but fluctuating temperatures, you’ll be running A/C units for about 4.6 months out of the year, which comes out to 38.33% of the year.

Using these numbers along with the ASHRAE rule of thumb, which states that 30 to 35 watts of cooling is required to offset the heat output for every 100 watts used to light a space, we can calculate how much energy it would take to cool the space just to offset the higher wattage lighting.

We’ll stick with the same $0.11 per kWh for the purposes of figuring out our savings.

183.6 wWh (annual savings per bulb) x 38.33 (percent of year for cooling) x .33 (ASHRAE rule) = 23.22 (kWh of HVAC energy savings per year)

23.22 wWh savings x $0.11 per kWh = $2.55 saved per bulb per year

Granted, $2.55 per bulb per year doesn’t sound like too much. But in our example we were running 100 bulbs, which brings that total to $250 per year in savings. That’s basically free money you’re getting back in cooling costs.

Maintenance costs

It’s difficult to do any kind of calculations here to figure out maintenance costs since every building, company, and installation is different. However, it’s not uncommon to require some kind of equipment rental to change expired bulbs. Whether those are specialized lifts or trucks or whatever other means are required to reach those out-of-the-way bulbs.

There’s also the labor cost of having someone take the time to find the replacement, get a ladder, change out the bulb, return the later, etc.

These costs (and their frequency) should be factored into your savings as well.

Material costs

HardWire’s LED bulbs last much, much longer than traditional incandescents. In fact, HardWire’s A19 LEDs have an expected lifespan of 15,000 hours. Couple that ultra-long lifespan with HardWire’s 10-year warranty, and there should be no need to replace bulbs for many years.

Additional considerations

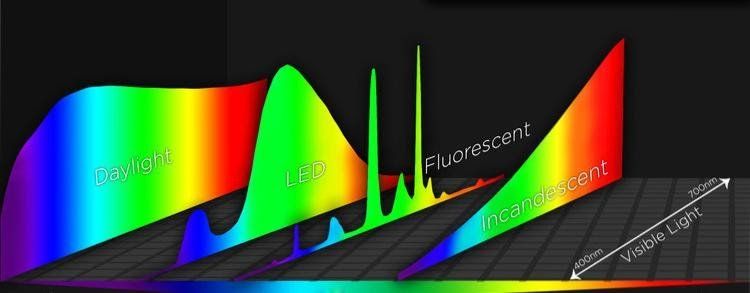

There are some unquantifiable “soft” costs to not upgrading to LED. Namely, lighting quality and its effect on your customers. As we discussed

in this article, your lighting has an effect on your customers whether they are consciously aware of it or not. Not upgrading to LED and running lower-quality lighting longer than necessary can have a real, if difficult to specify, negative impact on your sales and customer satisfaction.

Upgrading to LED can drastically improve your lighting quality, reduce your costs, and, in some cases, reduce the number of fixtures you need to achieve the same, or even better, lighting coverage.

If you’re ready to upgrade your lighting,

contact us for a free consultation.